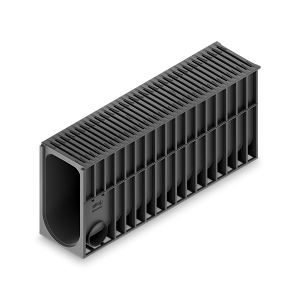

Load class according to EN 1433

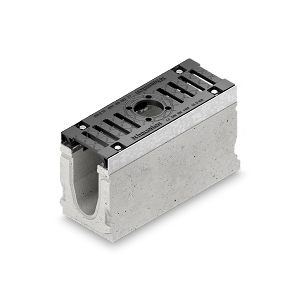

Load class according to EN 1433

up to F 900

up to F 900

up to D 400

up to F 900

Nominal width | System size

Nominal width | System size

3000, 5000, 8000

100 – 500

100 & 200

100 & 150

Materials of the lower parts

Materials of the lower parts

Modified polypropylene (PP), 100 % recycled composite

Fibre-reinforced concrete

Modified polypropylene

Liquid-tight concrete as a precast reinforced concrete element

Angle housing

Galvanised steel or ductile iron edge rail with 40 x 40 mm insertion depth

Galvanised steel or stainless steel angle housing with 40 x 40 mm insertion depth

Cover variants

Retained ductile iron slotted top

– Ductile iron covers

– GUGI ductile iron covers

Integrated award-winning FIBRETEC heelsafe design

– Ductile iron slotted covers

– Ductile iron covers

Special characteristics

– Radial installations possible

– Large channels for retention

– Channel run without slotted top achievable, for example, under planted areas

– Cable installations can be threaded though throat voids of the channel

– SIDE-LOCK, boltless locking system

– 16 fixing points for cover/metre

– Large retention volume despite slim channel design

– Monolithic drainage channel

– Vandalism-proof

– Easy cleaning via the inspection box

– Irrigation and drainage system (EFD and ESD)

– Corrosion-free, modular design in a recurring, fixed grid as a handy “plug-in” construction- Boltless locking system SIDE-LOCK

– 16-fold fixing options for the cover per metre

– Uniform irrigation of the carriageway

– Extremely low throw height (8-10 cm) and throw range (30-40 cm) of the water jet

Gradient

– Constant depth

– Stepped fall

– Constant depth

– Built-in fall (150, 200, 300)

– Stepped fall

– Constant depth

– Stepped fall